Cut laminations are a crucial component in the manufacturing of electrical machines and transformers. They consist of thin sheets of magnetic material, typically silicon steel or other specialized alloys, stacked together to form the core of these devices. The term "cut" refers to the process of shaping these laminations into specific geometries to meet design requirements. The primary purpose of cut laminations is to reduce eddy current losses within the core, which occur when a changing magnetic field induces circulating currents in conductive materials. By using thin, insulated layers, the path for these currents is limited, significantly improving the overall efficiency of the device. Cut laminations come in various shapes and sizes, including E-I, U-I, and toroidal configurations. The cutting process can be achieved through several methods, such as stamping, laser cutting, or wire electrical discharge machining (EDM). Each method offers different advantages in terms of precision, cost, and production volume. The thickness of individual laminations typically ranges from 0.1 to 0.5 mm, with thinner sheets generally providing better performance but at a higher cost. The laminations are often coated with insulating materials to further reduce inter-laminar eddy currents.In addition to their use in transformers and motors, cut laminations find applications in inductors, generators, and other electromagnetic devices across various industries, including automotive, renewable energy, and consumer electronics.

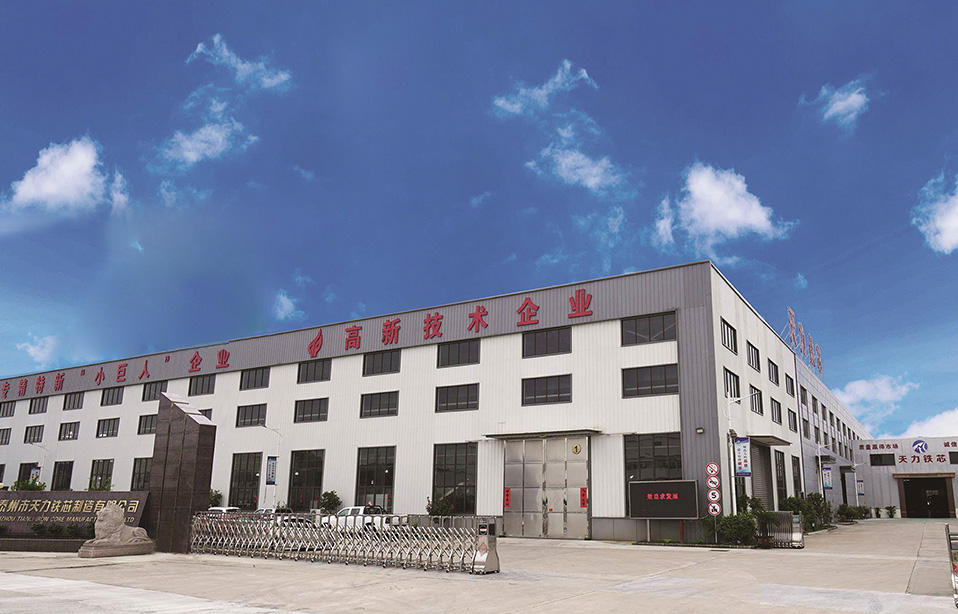

Taizhou Tianli Iron Core Manufacturing Co., Ltd. is China Transformer Cut laminations manufacturers and OEM/ODM Steel core laminations suppliers. Established in 2009, Tianli Iron Core is a leading full-solution provider of transformer core materials and assemblies. We specialize in slitted coils, core laminations, and precision-assembled magnetic cores for distribution and power transformers. With a strong technical foundation and materials sourced from top-tier mills like Shougang and Baosteel, we deliver reliable, high-performance solutions tailored to each client’s needs. Our experienced team ensures quality, flexibility, and responsive service across global markets. From material selection to final core assembly, Tianli is committed to powering your success—efficiently and dependably.

Your trusted partner in transformer core excellence.

Silicon steel mother coils, often referred to as electrical steel or transformer steel, are critical materials in the electrical and energy industries...

View MoreDry-type transformers are widely used in commercial and industrial settings due to their unique advantages in terms of safety, reliability, and enviro...

View MoreSilicon steel slitting coils play a critical role in the manufacturing of electrical transformers, motors, and other electromagnetic devices. They are...

View MoreTransformer cores are at the heart of modern power distribution systems. Their function is to provide a magnetic path that efficiently transfers energ...

View MoreDry-type transformers are essential components in electrical distribution systems, particularly in commercial, industrial, and residential environment...

View MoreHow do cut laminations help reduce core losses and improve overall efficiency?

Cut laminations help reduce core losses and improve overall efficiency in electrical machines, transformers, and other electromagnetic devices primarily by addressing two key types of losses: eddy current losses and hysteresis losses.

Reduction of Eddy Current Losses

Eddy currents are loops of electrical current induced within conductive materials when they are exposed to changing magnetic fields. These currents generate heat and lead to energy losses. Cut laminations significantly mitigate this issue by:

Using thin, insulated sheets: Instead of a solid core, which allows eddy currents to circulate freely, cut laminations are made of thin sheets of magnetic material (typically silicon steel). These sheets are electrically insulated from one another, often with a thin coating.

Breaking up the current paths: By stacking thin layers with insulation between them, the lamination structure limits the size of the paths available for eddy currents to form. This reduces the magnitude of these currents and thus minimizes the energy wasted as heat.

In essence, the thinner and better-insulated the laminations, the smaller the eddy currents, which leads to improved energy efficiency.

Reduction of Hysteresis Losses

Hysteresis losses occur due to the repeated magnetization and demagnetization of the core material as it is subjected to alternating magnetic fields. These losses are proportional to the area of the material's hysteresis loop, which describes the relationship between the magnetic field strength and the induced magnetic flux.

High-quality magnetic materials: Cut laminations are typically made from specialized magnetic materials like silicon steel, which have lower hysteresis losses compared to other materials. The composition and treatment of these materials reduce the energy required to magnetize and demagnetize the core.

Thin laminations: Thinner laminations help improve the core's response to the changing magnetic fields, further reducing hysteresis losses.

Improved Magnetic Properties

Laminations made from specialized alloys, such as grain-oriented silicon steel, have enhanced magnetic properties, which means less energy is required to establish the magnetic field within the core. This not only reduces core losses but also boosts the overall efficiency of the device.

Optimized Core Design

The precise cutting and stacking of laminations into specific shapes (like E-I, U-I, or toroidal configurations) allow for optimized magnetic flux paths. These optimized paths reduce magnetic leakage and ensure that more of the magnetic energy is efficiently transferred through the core, contributing to better performance.