In modern electrical and industrial engineering, material performance is critical to efficiency, durability, and overall system reliability. Among the essential materials in this sector are silicon steel slitting coils, which are widely used in the manufacturing of transformers, motors, generators, and other high-performance electrical devices. But what exactly are silicon steel slitting coils, how are they produced, and why are they indispensable in energy and industrial applications?

What Are Silicon Steel Slitting Coils?

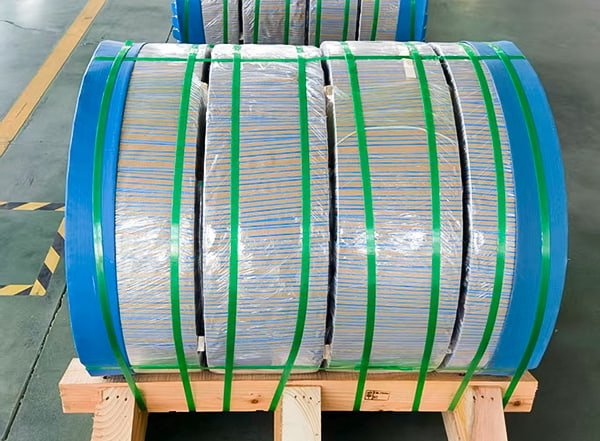

Silicon steel slitting coils are thin sheets of high-quality silicon steel that have been cut (slit) into narrower widths to meet precise industrial requirements. Silicon steel itself is an alloy of iron with a small percentage of silicon, typically ranging from 1% to 4%. This addition of silicon significantly enhances the electrical and magnetic properties of the steel, including reduced hysteresis and eddy current losses.

The slitting process transforms large coils into custom-width strips, making them ready for use in the production of electrical laminations, core assemblies, and other components that require exact dimensions.

Why Is Silicon Steel Used in Electrical Applications?

Silicon steel is widely favored in the electrical industry for several reasons:

Reduced Core Losses – Silicon improves the steel’s magnetic properties, minimizing energy loss in transformers and motors.

High Magnetic Permeability – Enhances the material’s ability to conduct magnetic flux efficiently.

Thermal Stability – Maintains performance at elevated temperatures, essential for industrial and power equipment.

Mechanical Strength – Offers durability during manufacturing, handling, and assembly processes.

Resistance to Oxidation – Silicon content improves corrosion resistance, extending the service life of components.

By using silicon steel, manufacturers can optimize energy efficiency and performance in electrical devices.

How Are Silicon Steel Slitting Coils Manufactured?

The production of slitting coils involves a series of precision engineering steps to ensure high-quality material performance:

Casting and Rolling – Silicon steel is cast into slabs and hot-rolled to the desired thickness.

Cold Rolling – Further reduction in thickness improves surface finish, dimensional accuracy, and mechanical properties.

Annealing – Heat treatment relieves stress and enhances magnetic properties.

Coating – Electrical insulation coatings are applied to minimize eddy current losses in laminated assemblies.

Slitting – Large coils are precisely cut into narrower widths to meet the specifications required by the electrical industry.

Quality Control – The coils undergo rigorous inspection for thickness tolerance, surface finish, and magnetic performance.

This meticulous production process ensures that silicon steel slitting coils deliver consistent quality and optimal performance.

What Are the Key Features of Silicon Steel Slitting Coils?

Precision Widths and Thickness – Slitting ensures uniformity, which is essential for assembling electrical cores.

High Magnetic Performance – Low core losses and high magnetic permeability improve energy efficiency.

Surface Smoothness – Minimizes friction and reduces losses in laminated cores.

Durability – Resistant to mechanical stress during handling and operation.

Versatility – Suitable for different grades, including grain-oriented (GO) and non-oriented (NO) silicon steel.

These features make silicon steel slitting coils critical in modern electrical manufacturing.

How Do Grain-Oriented and Non-Oriented Silicon Steel Differ?

Grain-Oriented (GO) Steel – Magnetic domains are aligned during production, resulting in higher efficiency in one direction, ideal for transformer cores.

Non-Oriented (NO) Steel – Magnetic properties are uniform in all directions, making it suitable for rotating machinery like motors and generators.

Selecting the appropriate type depends on the specific application, efficiency requirements, and magnetic flux orientation.

What Are the Applications of Silicon Steel Slitting Coils?

Silicon steel slitting coils are widely used in industrial and electrical sectors:

Transformers – Laminated cores made from slit coils reduce energy loss and improve efficiency.

Electric Motors – Non-oriented coils enhance performance and reduce heat generation.

Generators – High magnetic permeability and low losses improve energy conversion efficiency.

Inductors and Reactors – Minimized core losses enhance performance in power conditioning and control systems.

Power Equipment – Critical in high-voltage and high-current applications, providing both stability and reliability.

Their widespread use underscores their essential role in efficient, high-performance electrical systems.

How Does Slitting Enhance the Value of Silicon Steel?

The slitting process allows manufacturers to:

Optimize Material Usage – Reduces waste by producing strips that match the exact dimensions needed.

Ensure Uniformity – Narrow strips maintain consistent thickness and width for precise assembly.

Facilitate Assembly – Pre-cut strips simplify the production of laminated cores and other components.

Improve Efficiency – Properly sized strips reduce time and labor in manufacturing operations.

By transforming large coils into ready-to-use strips, the slitting process adds practical value and efficiency to the production chain.

How Are Silicon Steel Slitting Coils Maintained and Stored?

Proper care ensures longevity and performance:

Clean Storage – Keep coils free from dust, moisture, and corrosive substances.

Temperature Control – Avoid extreme temperatures that can affect magnetic properties.

Protective Coatings – Ensure insulation coatings are intact to prevent eddy current losses.

Handling – Use suitable equipment to prevent mechanical damage to the edges or surface.

Adhering to these practices guarantees reliable performance during manufacturing and operation.

What Are the Advantages of Using Silicon Steel Slitting Coils?

High Efficiency – Low core losses contribute to energy savings in electrical devices.

Precision Manufacturing – Slitting ensures strips meet exact industrial requirements.

Versatility – Applicable in a wide range of electrical and industrial machinery.

Durability – Withstands mechanical stress and high-temperature environments.

Cost-Effectiveness – Reduces material waste and improves production efficiency.

These advantages explain why silicon steel slitting coils are a staple in modern electrical manufacturing.

Final Thoughts: Why Are Silicon Steel Slitting Coils Indispensable?

Silicon steel slitting coils are fundamental to the efficiency, durability, and performance of electrical devices. From transformers and motors to generators and industrial power equipment, these coils provide reduced energy losses, high magnetic permeability, and structural reliability.

+86-523 8891 6699

+86-523 8891 6699  +86-523 8891 8266

+86-523 8891 8266  info@tl-core.com

info@tl-core.com  No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

English

English Español

Español Türk

Türk 中文简体

中文简体