In the modern world, where electricity powers almost every aspect of life, the efficient distribution of electrical energy is essential. At the core of this system lies a vital component — the Power Distribution Transformer Core. This key element is central to the function of distribution transformers, enabling the safe and efficient transmission of electricity from power plants to residential, commercial, and industrial users.

Structure and Materials

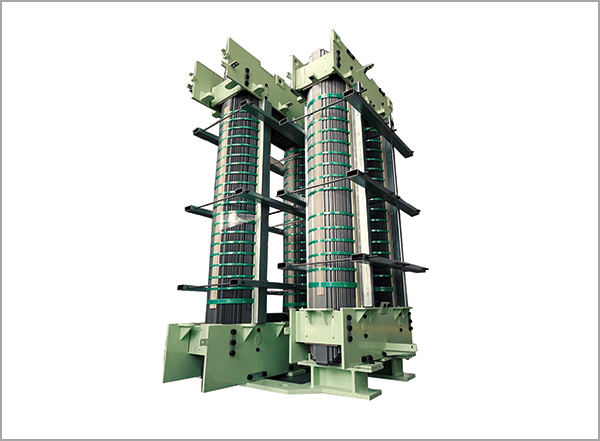

Typically, transformer cores are built using cold-rolled grain-oriented (CRGO) silicon steel, known for its high magnetic permeability and low hysteresis loss. This material helps reduce core losses, including eddy current loss and hysteresis loss, which can affect the overall efficiency of the transformer. To further reduce losses, the core is constructed using thin, insulated steel laminations stacked together, rather than a single solid piece of metal.

Two common core configurations are:

Core Type: In this structure, the windings surround the core limbs. It offers good mechanical strength and is widely used in power transformers.

Shell Type: The core surrounds the windings in this configuration. It provides better short-circuit strength and is commonly used in distribution transformers.

Working Principle

The core operates on the principle of electromagnetic induction. When alternating current (AC) flows through the primary winding, it generates a magnetic flux in the core. This magnetic flux is then linked to the secondary winding, inducing a voltage proportional to the primary voltage but adjusted according to the turns ratio. The magnetic properties of the core determine how efficiently this energy is transferred.

Importance in Power Distribution

The transformer core significantly affects the performance, energy efficiency, and noise level of a distribution transformer. A high-quality core material ensures minimal energy loss, reduced operational heat, and extended transformer life. This is crucial for distribution transformers, which are often in continuous operation and form the final step in the electricity delivery system to end-users.

Efficient transformer cores also contribute to:

Reduced carbon footprint by minimizing energy loss during transmission.

Lower maintenance costs due to improved thermal performance.

Greater reliability in power supply for households, businesses, and critical infrastructure.

Innovations and Trends

With increasing demand for energy efficiency, modern transformer cores are evolving. Amorphous metal cores are an advanced alternative to traditional silicon steel. They offer lower core losses and are particularly useful in eco-friendly, energy-saving transformers. Although they are more expensive, the long-term savings on energy loss make them a viable choice for sustainable power distribution systems.

Additionally, advances in design optimization, AI-driven core manufacturing, and 3D modeling are helping manufacturers produce lighter, more efficient cores with reduced material usage and improved magnetic performance.

The power distribution transformer core may not be visible to the average electricity consumer, but it plays a crucial role in ensuring that electricity is delivered efficiently and reliably. As the world shifts toward smarter and greener energy systems, the development of more efficient and sustainable transformer cores will be at the forefront of innovation in power distribution. Their importance as the "heart" of the transformer cannot be overstated — they are indispensable to the pulse of modern civilization.

+86-523 8891 6699

+86-523 8891 6699  +86-523 8891 8266

+86-523 8891 8266  info@tl-core.com

info@tl-core.com  No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

No.1, Third Industrial Park, Liangxu Street, Taizhou City, Jiangsu, China

English

English Español

Español Türk

Türk 中文简体

中文简体